Next-Generation Glass Defect Inspection using AI

Glass Defect Inspection with sub-micron capability

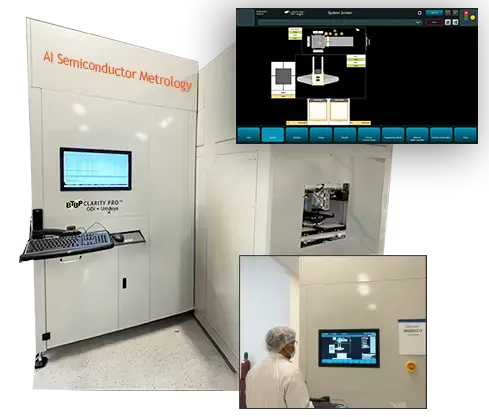

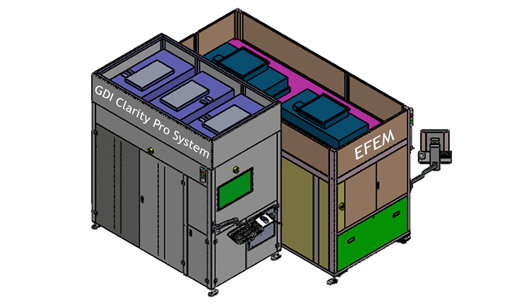

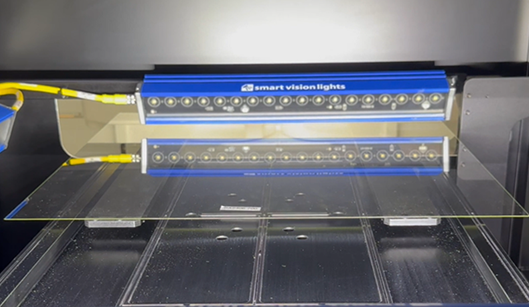

GDI Clarity Pro redefines precision in glass defect inspection with cutting-edge optics and advanced surface scanning. Capable of detecting defects as small as sub-micron levels with a spatial resolution of 2.5 µm, it delivers unmatched edge and through-surface defect analysis. Defect classification & measurement done real-time, with no throughput overhead.

The system offers:

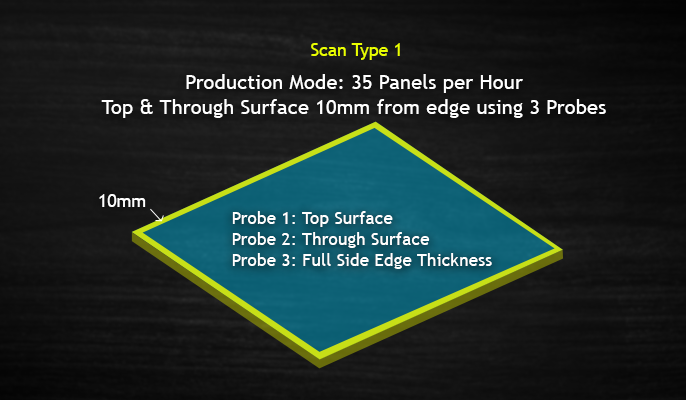

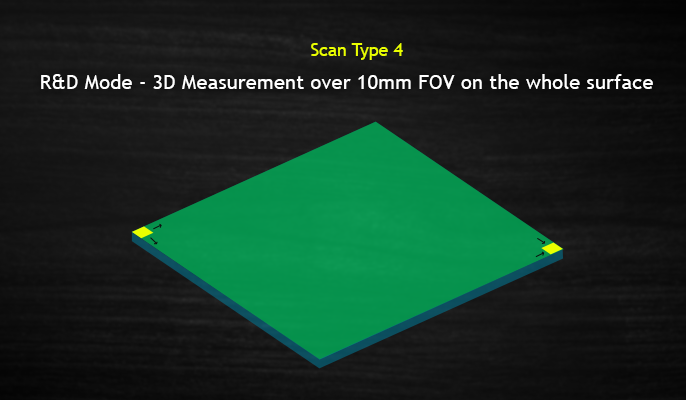

- Production Mode: 35 Panels per Hour, Edge inspection Top & Through Surface 10mm using 3 Probes

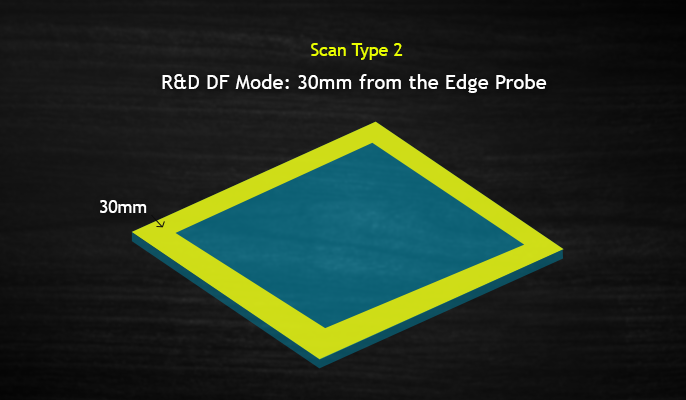

- Advanced R&D mode with 2D and 3D inspection capabilities with Z-axis resolution of <1 nanometer

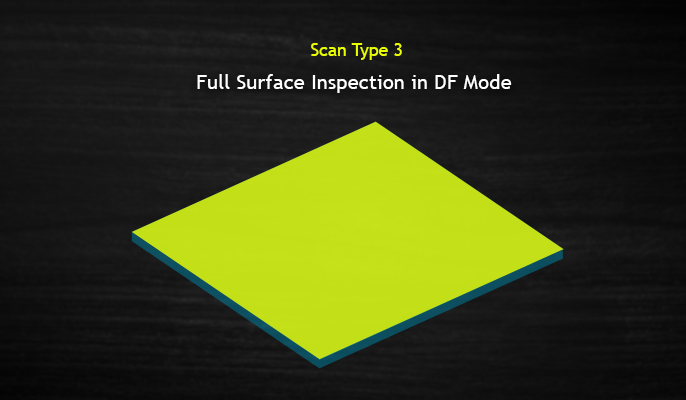

- Full-panel macro-surface scanning for holistic defect identification

- 30mm edge-detection range for surface inspection

Engineered for Semiconductor industries demanding the highest quality. GDI Clarity Pro brings absolute transparency to defect detection.

How it works

Highlights

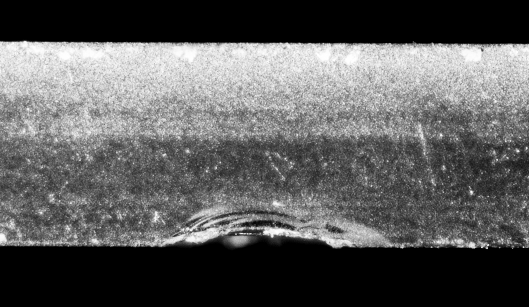

DEFECTS ON GLASS SUBSTRATES

Chips <1 μm

Edge defects <1 μm

Cracks <1 μm length and ≥5 μm depth (in Z)

Scratches <1 μm length and <5 μm depth (in Z)

FM (foreign material) <1 μm

Surface Pitting <1 μm

Stains and FM are classified separate from other defect types

Classification >5 μm

E-MCBFp* > 20,000 cycles with uptime >95%

Supplier dependent scheduled downtime <1%

Substrate Form Factor Size(s) Less than 520mm

Production Run Rate 35 full substrates/hour

Automatic Defect Classification (ADC) Yes

Image Processing Fully Trained AI

Defect Size Repeatability 3-sigma < 10%

Same defect measured at least 20 times to calculate 3-sigma.

Defect Image Capture

Variable magnification review image automatically

saved for visual defect review/classification

R&D Applications

3D-Profile(Mapping) with Z-Height Measurement (>1nm)

Active Area Surface 10mm Inspection Sampling

Equipment Matching/Calibration

Calibration done using Polystyrene or Glass Spheres

Maximum substrate warpage 5mm

Substrate thickness range :

200 microns to 10mm thickness

Automated loading 520mm substrates.

Manual loading <520mm substrates.

Cleanroom Requirement

Class 100

Equipment internal

Class 10

Electrostatic Discharge (ESD)

Ionizer performance±3V

FACILITIES & ELECTRICAL SPECIFICATIONS

Voltage 208 V AC

Number of Phases 1 Phase

Wiring Configuration 3 Wire, 1 Line, 1 Neutral, 1 Ground

Frequency 50/60 Hz

Full Load Current 36 Amps

Non-Continuous Current 12 Amps

Continuous Current 24 Amps

Machine OCP Device Rating 50 A

Ampere of Largest Load 20 A

Air 100 Psi

Vacuum -85 Kpa

SemiConductor Fab Host Fully SEMI Compatible